years of

experience

M2

Built-up area

We have a strong R&D team,and we can develop and produce Plastic Valve according to the drawings or samples the customers offered.

We are manufacturer, so we can offer the good price and good Valve fittings directly.

We have our own testing lab and the advanced and complete inspection equipment,which can ensure the quality of the Plastic Valves.

We are located in Ningbo Port area,so it is very convenient and efficient to ship goods to any other countries.

The company owns the abundant technical force and testing Means, gather the advanced technical advantages and precise manufacture equipments ,assemble a group of the technicians who are capable of researching into;developing and producing the complicateds and machine tools, It Iays asolid guarantee to the equipment quality.

We aim to meet all our customers’ request by good quality and service. Welcome your inquiry and visits!

During the installation of the automatic butterfly valve, the preliminary preparation work is crucial. First of all, it is necessary to carefully check the model and specifications of the selected automatic butterfly valve to ensure that it is perfectly matched with the pipeline system. In addition,...

During the installation of automatic butterfly valves, the sealing surface problem is one of the common faults, which directly affects the performance and reliability of the valve. Damage to the sealing surface or the presence of impurities is the main cause of leakage. Before the valve is installed...

In modern industrial pipeline systems, reducing tees are important connecting components, and their maintenance is essential to ensure the efficient operation of the system. Regular inspection and maintenance can not only extend the service life of reducing tees, but also effectively prevent potenti...

In the modern industrial field, reducing tees, as important pipeline connection components, undertake the key functions of fluid transportation and distribution. Its design and material selection directly affect the overall performance and reliability of the pipeline system. Therefore, when selectin...

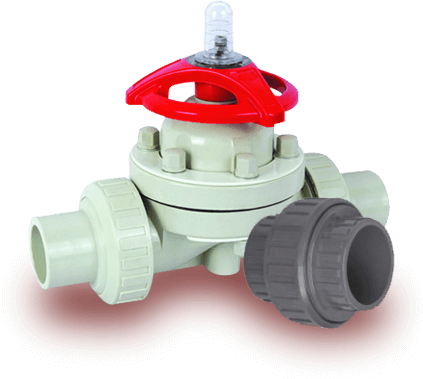

As a key component in the fluid control system, the performance of the manual diaphragm valve is directly related to the safety and efficiency of the entire system. As the core component of a manual diaphragm valve, the quality of its condition will directly affect the sealing performance and servic...

Maintenance and maintenance of manual diaphragm valves is the key to ensuring their long-term and stable operation, and regular inspections are the basis of maintenance work. It is crucial to conduct a comprehensive inspection of the valve's appearance, sealing surface, transmission components and c...